Frost Heave Prevention Testing with Slickcoat

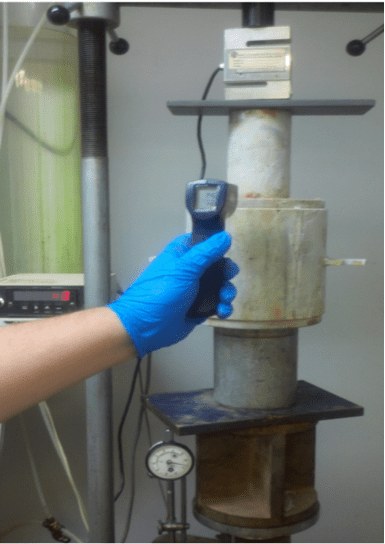

Frost heave problems have plagued many projects in Canada and the Northern regions of the U.S. for years. Especially problematic are lightly loaded structures founded on steel piles extending to relatively shallow depths. In order to evaluate these frost heave problems, Sailors Engineering Associates, Inc. performed laboratory testing to evaluate the effect of various pipe coatings on small diameter steel pipes.

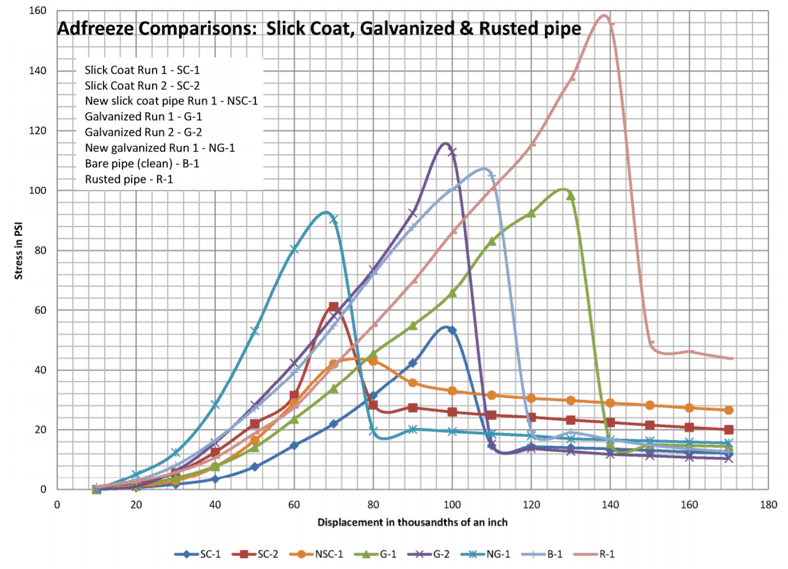

Two methods were used to apply the SLICKCOAT™coating - one with the product brushed on leaving some brush marks (SC-1/SC-2) and another with the product spray applied (NSC-1). Two galvanized pipe sections (G-1/G-2 and NG-1) were used. One bare pipe with factory applied rust protection for storage and shipping (B-1) and one lightly rusted pipe (R-1) were also used.

A graph of the results obtained shows the typical shape of adfreeze stress versus deflection reported by other researchers.

The shape includes a peak adfreeze bond stress followed by a much lower residual adfreeze stress after the initial bond has been broken. Except for the rusted pipe section, the residual adfreeze stresses were within a range of 75 to 190 kPa. The peak adfreeze stress values for the brush applied slick coat pipes were 368 and 421 with an average of 395 kPa. The spray applied SLICKCOAT™ pipe had a peak adfreeze stress of 296 kPa. The galvanized sections had peak adfreeze stresses of 678 to 778 with an average of 728 kPa. The bare pipe with the factory applied temporary rust protection had a peak value of 725 kPa while the lightly rusted pipe had a peak value of 1073 kPa.

Regardless of the adfreeze stress design values used for frost heave calculations, the actual peak value experienced in the field is dependent upon the condition of the surface of the pile. Our research indicates that the use of SlickCoat™ would greatly reduce the value to about 28 percent of that of lightly rusted pile.

Read the full Adfreeze Bond Stress Reduction Test Report.