BARBOOT® Rebar Supports

BARBOOT® is a simple and economical way to support and space vertical rebar at the base of drilled shaft foundations. BARBOOT® plastic rebar supports stabilize the entire reinforcement cage and maintain proper clearance between the cage and the shaft bottom. Encapsulating the rebar ends also helps protect against corrosion at this critical location.

BARBOOT® supports improve quality assurance for installers, engineers, inspectors, and owners by helping ensure the reinforcement cage is consistently positioned off the base of the shaft.

View the BARBOOT® Rebar Supports Product Sheet.

BARBOOT® plastic rebar boots: We've got your clearance covered.

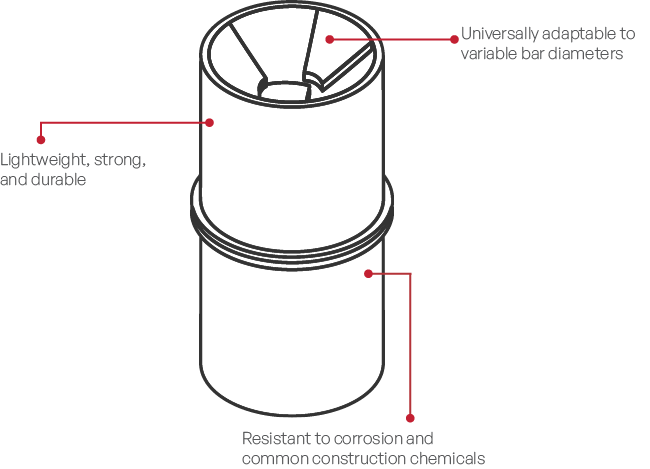

BARBOOT® rebar boots position reinforcement cages consistently and install quickly. These self-locking, high‑density plastic supports are purpose‑built for drilled shaft construction and provide confidence that rebar cages are properly spaced and held off the base of the shaft throughout the pour.

BARBOOT® supports are universally adaptable to a wide range of bar sizes (one size fits #5–#18).

BarBoot® Sizes

Model |

Cover

|

Bar Size |

Packaging |

| BB711 | 3.0" | #5–#18 | 50 |

| BB711-6 | 6.0" | #5–#18 | 25 |

BARBOOT® models will fit #18 bar. Please call to verify cage weight and quantity requirements.

BARBOOT® Minimum Placement Recommendations

- Equally space rebar boots around the bottom of the cage

- Use one BARBOOT® per 1,500 lbs of steel cage weight

- Minimum of one BARBOOT® on every other vertical bar

Frequently Asked Questions

What rebar sizes does BarBoot® fit?

BarBoot® is a one-size solution that fits #5 through #18 rebar.

Does BarBoot® help prevent corrosion?

Yes. BarBoot® encapsulates the rebar ends at the shaft bottom, helping protect against corrosion at a critical exposure point.

How many BarBoot® supports do I need?

Use one BarBoot® per 1,500 lbs of steel cage weight, with at least one on every other vertical bar, spaced evenly around the cage.

Can I use BarBoot® on DOT and bridge foundations?

Yes. BarBoot® is commonly used in drilled shaft foundations for DOT, bridge, and other infrastructure projects.

Is BarBoot® compatible with slurry or tremie pours?

Yes. BarBoot® is designed for drilled shaft work and maintains cage clearance during slurry or tremie placements.

What material is BarBoot® made from?

High‑density, corrosion‑resistant plastic designed for durability in drilled shaft environments.

What cover heights are available?

Models include BB711 (3.0" cover, 50/box) and BB711‑6 (6.0" cover, 25/box).

If Your Drilled Shaft Project Requires CSL Testing, Then Consider Sonitec® CSL Tubes

If your project specifications call for crosshole sonic logging (CSL) integrity testing, Sonitec® CSL tubes are designed for reliable installation and accurate results in demanding foundation conditions.

- Meets common DOT and drilled shaft project requirements

- Durable, job-site–ready construction

- Installs easily with your rebar cage assembly

- Bundle with your BarBoot® order for coordinated delivery and potential freight savings

Request a Quote

Have questions about any of our foundation products? Ready to get started on your next project? Looking for expert advice? Request a quote now to speak with our team about specifications, quantities, and placement recommendations. We’ll get back to you within one business day.