CageCaster® Rebar Cage Spacers

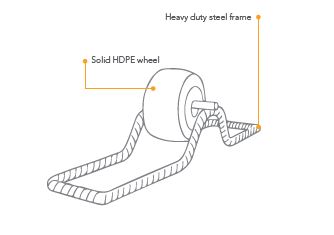

The CageCaster® rebar casing spacer is a heavy-duty steel frame with a solid HDPE wheel used to centralize heavy reinforcing steel cages within drilled shafts, rock sockets, and battered drilled shafts—including spiral reinforcing steel cages. CageCaster® spacers provide the support needed during cage installation and help keep the rebar cage centered throughout concrete placement.

The CageCaster® rebar casing spacer is a heavy-duty steel frame with a solid HDPE wheel used to centralize heavy reinforcing steel cages within drilled shafts, rock sockets, and battered drilled shafts—including spiral reinforcing steel cages. CageCaster® spacers provide the support needed during cage installation and help keep the rebar cage centered throughout concrete placement.

*Zinc Coated Available

*Zinc Coated Available

View the CageCaster® Rebar Spacer Product Sheet.

CageCaster® rebar cage spacers properly position reinforcement cages every time.

The CageCaster® heavy-duty rebar centralizer installs with the same tie wire used to assemble the reinforcing steel cage. Built for drilled shaft construction, these spacers provide quality assurance for drillers, contractors, engineers, and inspectors by helping ensure the reinforcement cage is consistently centered and held off the shaft surface during placement.

Model |

Cover |

Bar Size |

Packaging |

Weight |

| CC250HD | 2.5" | n/a | Sold Individually | 1.7 lb ea |

| CC300HD | 3" | n/a | Sold Individually | 1.7 lb ea |

| CC350HD | 4" | n/a | Sold Individually | 1.7 lb ea |

| CC450HD | 5" | n/a | Sold Individually | 2.2 lb ea |

| CC550HD | 6" | n/a | Sold Individually | 2.2 lb ea |

*Custom sizes greater than 6" cover can be made upon request.

CageCaster® Rebar Cage Spacer Placement Recommendations

- Use one CageCaster® per foot (304.8 mm) of shaft diameter (minimum of four per tier)

- Maximum 6 ft (1.83 m) spacing from the top of the shaft

- Maximum 2 ft (0.61 m) spacing from the bottom of the shaft

- 10–14 ft (3.05–4.27 m) interval spacing along the longitudinal axis of the shaft

Placement recommendations are based on typical conditions. Please contact our team for project-specific guidance.

If Your Drilled Shaft Project Requires CSL Testing, Then Consider Sonitec® CSL Tubes

If your project specifications call for crosshole sonic logging (CSL) integrity testing, Sonitec® CSL tubes are designed for reliable installation and accurate results in demanding foundation conditions.

- Meets common DOT and drilled shaft project requirements

- Durable, job-site–ready construction

- Installs easily with your rebar cage assembly

- Bundle with your CageCaster® order for coordinated delivery and potential freight savings

Frequently Asked Questions

What does CageCaster® do?

It centralizes and supports drilled shaft rebar cages using a steel frame and solid HDPE wheel, helping keep the cage centered during installation and concrete placement.

Is CageCaster® compatible with spiral cages and battered shafts?

Yes. CageCaster® is designed for spiral reinforcing cages and for use in rock sockets and battered drilled shafts.

How is CageCaster® attached to the cage?

It ties on with the same tie wire used to assemble the cage—no special tools required.

Is a zinc-coated version available?

Yes. Zinc-coated CageCaster® models are available; contact us for availability and lead times.

What cover heights are available?

Standard models provide 2.5", 3", 4", 5", and 6" cover. Custom cover sizes greater than 6" are available upon request.

Is CageCaster® suitable for DOT or bridge work?

Yes. CageCaster® is commonly used on DOT and infrastructure projects for drilled shaft foundations.

What are the basic placement recommendations?

Use one unit per foot of shaft diameter (minimum four per tier), with no more than 6 ft from the top and 2 ft from the bottom; space tiers every 10–14 ft along the shaft.

How do I get technical guidance or a quote?

Use our Request a Quote form to share your shaft diameter, length, and cage details. We’ll respond quickly with quantity and placement guidance.

Request a Quote

Have questions about any of our foundation products? Ready to get started on your next project? Looking for expert advice? Request a quote now to speak with our team about specifications, pricing, and placement recommendations. We’ll get back to you within one business day.